Need a tangible representation of your concept? CNC prototype machining provides a precise and efficient solution. Whether you’re looking for a unique piece or a series tailored for a functional assembly, our services can bring your ideas to life.

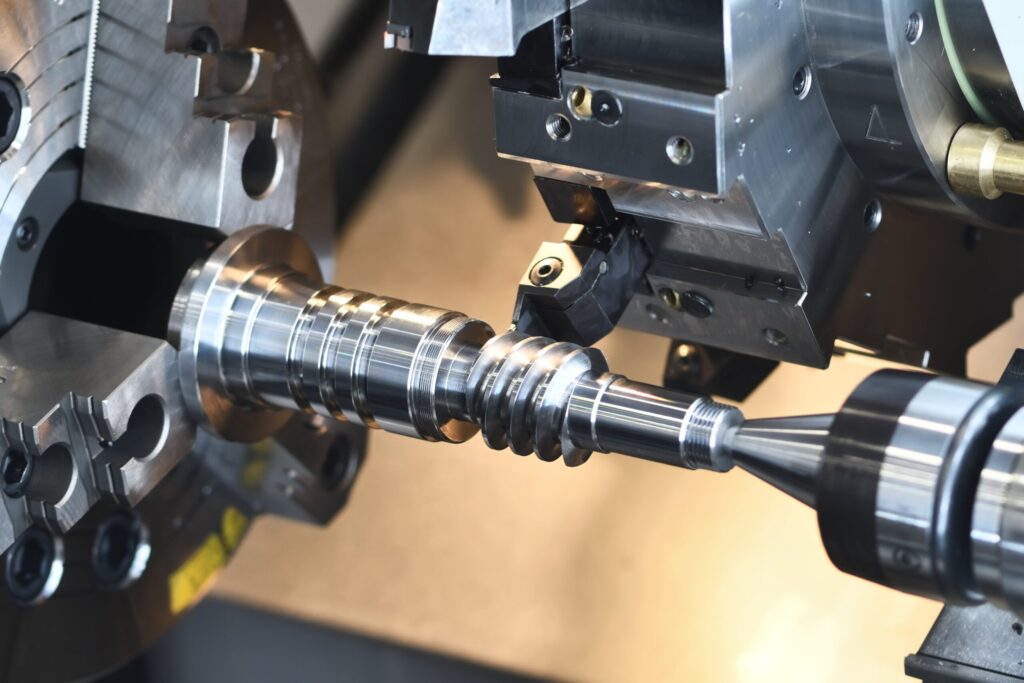

We believe in giving you the most authentic experience. That’s why we use genuine materials—whether it’s aluminum, steel, brass, or plastics—and trusted production methods. This approach ensures that your prototype mirrors its eventual performance. While 3D printing has its merits, we prioritize CNC milling and lathe operations, as real-world materials often reveal vital insights about a part’s viability.

WHY CHOOSE CT&F FOR PROTOTYPE MACHINING?

GOT A CONCEPT?

Bring us your sketches, existing blueprints, or digital models. We’re here to suggest the best production method and craft your prototype. Reach out today to discuss your vision or request a complimentary quote

When precision meets scalability, the results are unparalleled. At CT&F, we don’t just stop at prototypes. Our CNC production services seamlessly transition your validated concepts into full-scale manufacturing, ensuring that every piece matches the high standards set by your prototype. Crafted with diligence and advanced CNC machinery, our production capabilities encompass a range of materials, from aluminum and steel to brass and plastics. We believe in harnessing the latest techniques while ensuring the timeless quality and finish that CNC milling and lathe operations are known for.

WHY CHOOSE CT&F FOR CNC PRODUCTION?

READY FOR MANUFACTURING?

Whether it’s a fresh concept or a product evolved from our prototyping service, we’re poised to deliver. Contact us to learn more about our production capabilities or to obtain a detailed estimate.

Unveiling the future of machining with CT&F’s advanced CNC milling solutions. With our blend of traditional craftsmanship and cutting-edge technology, we curate precision-crafted parts tailored to a myriad of industries. TECHNOLOGICAL ADVANTAGES:

INTRODUCING OUR NEW DOOSAN MACHINES:

THE CNC MILLING JOURNEY:

Though CNC offers unmatched precision and scalability, the charm of manual milling remains. For designs with unique specifications or when you seek cost-effective solutions for prototypes and limited batches, our seasoned operators deliver using manual milling.

OPTIMIZED SOLUTIONS FOR YOU:

Whether it’s the advanced CNC milling or the nuanced manual approach, our goal remains consistent – to offer the most efficient and precise solution for your project. Discuss your requirements, and we’ll guide you to the best fit. Reach out now for a tailored quote.

Elevate your machining experience with CT&F’s state-of-the-art CNC turning solutions. Harnessing the capabilities of our high-speed lathes, we deliver precision-turned components tailored to diverse industries, ensuring a confluence of speed and accuracy. KEY FEATURES:

MEET THE DOOSAN PUMA 2600SYB II: Our new gem, the Doosan Puma 2600SYB II Dual Spindle Live Tool, revolutionizes turning:

YOUR CNC TURNING JOURNEY:

While CNC turning stands out for its precision and repeatability, the allure of manual turning is undeniable. Our manual lathes shine in crafting detailed and bespoke components, especially for designs requiring a hands-on touch. Whether it’s a one-off piece or a small batch, our experts might recommend manual turning for its efficiency and finesse.

GUIDANCE & EXPERTISE AT YOUR FINGERTIPS:

At CT&F, we pride ourselves on offering holistic solutions. Share your requirements and we’ll advise on the most efficient machining approach for optimal outcomes. Connect with us for a custom quote tailored to your needs.

Our CNC machining and milling services at Mountain CNC are unmatched in terms of quality and technology where we combine the old craftsmanship with the new age technology. We have been in the market since 1997 and proved to be a reliable supplier for those industries, where high standards are critical—aerospace, medical, defense, and electronics industries. Our commitment to excellence drives us to deliver meticulously crafted parts that exceed our clients’ exacting standards.

In CNC milling, precision and consistency are critical. That is why Mountain CNC remains your top choice. We utilize the latest technology and machinery at our CNC machining center to deliver exceptional results with flawless accuracy, no matter how intricate the geometrical angles of each part are. Here’s why we stand out:

Our approach to CNC milling is a finely tuned process designed to transform your concepts into reality with unmatched precision:

At Mountain CNC, we know that every job is different. Even if your needs include the most advanced CNC milling technologies or the craftsmanship of skilled professionals for complex and small-batch operations, we have the tools and the expertise to ensure your project is flawlessly accurate from start to finish, delivering your project on time and with exceptional quality.

Enhance your projects with our exceptional CNC milling services. Contact us now, and we’ll bring your ideas to life with spot-on accuracy.

Mountain CNC is the machining solutions partner you’ve been searching for. We are confident you will find our quality, service, and on-time deliveries an asset to your production team.

© Copyright 2024 Mountain CNC. All Rights Reserved. | Privacy Policy | Terms & Conditions